Injection Molding

Injection Molding

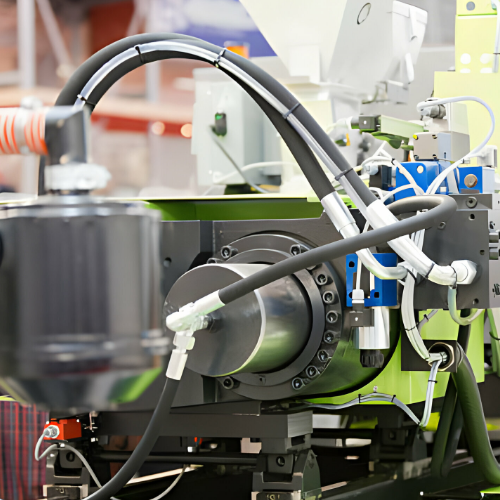

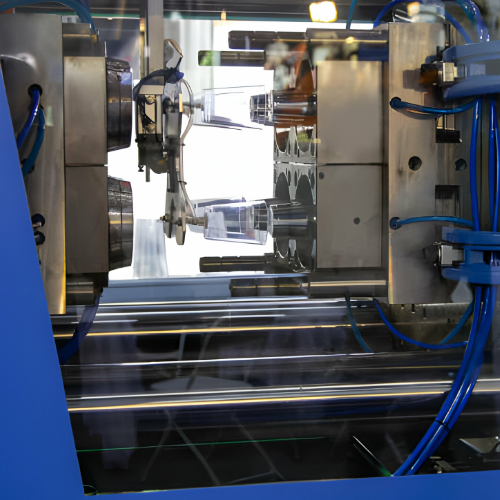

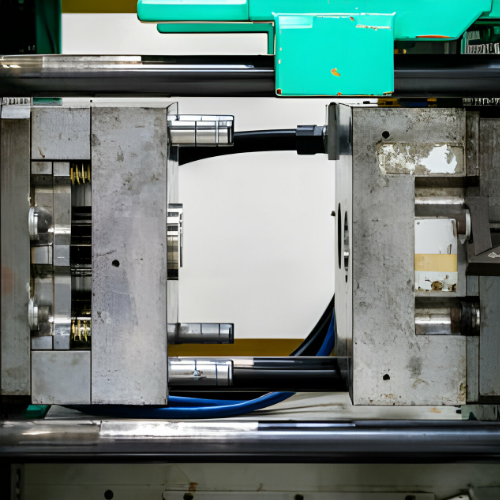

Injection molding stands as a cutting-edge manufacturing process that involves injecting molten material, often plastic, into custom molds to create intricate shapes and components. This versatile technique serves various industries and projects, offering unparalleled precision, speed, and design flexibility.

Injection molding stands as a cornerstone of modern manufacturing, shaping plastic materials into intricate products with unmatched precision. Our state-of-the-art process involves injecting molten plastic into custom molds, creating components that are integral to a multitude of industries. From consumer goods to medical devices, injection molding ensures durability, consistency, and aesthetic finesse.

Benefits of Injection Molding:

Unmatched Precision: Injection molding guarantees the production of intricate, consistent, and highly detailed parts. This precision minimizes errors and ensures that each component meets exact specifications.

Material Variety: A wide range of materials, including plastics, elastomers, and more, can be used in injection molding. This enables customization based on factors like strength, flexibility, and chemical resistance.

Rapid Production: Injection molding excels at mass production, producing a large volume of identical parts in a remarkably short span. This accelerated production timeline translates to quicker project completion.

Design Freedom: The technique allows for complex designs with fine details that might be challenging to achieve using other methods. This freedom fosters innovation and opens the door to diverse design possibilities.

Cost Efficiency: Injection molding’s ability to create multiple identical parts quickly makes it a cost-effective solution, particularly for projects with substantial quantities. The minimized labor and material costs contribute to overall savings.

Limitations of Injection Molding

Injection molding is a highly effective manufacturing process, but it also comes with certain limitations and potential downsides:

High Initial Tooling Costs: Developing the molds and tooling for injection molding can be expensive, especially for complex designs. The upfront investment in tooling might be a barrier for small-scale production or prototypes.

Lead Time for Tooling: Creating custom molds can take time, which can extend the lead time before production can begin. This might not be suitable for projects with tight deadlines.

Design Limitations: Injection molding has constraints on certain design features. Sharp corners, undercuts, and thin walls can be challenging to achieve without causing defects or challenges during ejection.

Material Selection: While injection molding offers a wide range of materials, not all materials are suitable for the process. Material properties like melting point, viscosity, and shrinkage can impact the feasibility of injection molding.

Surface Imperfections: Injection-molded parts might exhibit surface imperfections like sink marks, warping, or visible ejector pin marks. Additional finishing processes might be necessary to achieve the desired surface quality.

Size Constraints: The size of injection-molded parts is limited by the capacity of the molding machine. Extremely large parts might require alternative manufacturing methods.

Uniform Wall Thickness: Maintaining uniform wall thickness in injection-molded parts is important to prevent defects like warping and sink marks. Designing for consistent thickness can sometimes limit design creativity.

Tolerances and Variability: While injection molding can achieve tight tolerances, factors like material properties and tool wear can lead to variations in part dimensions. This might require additional quality control measures.

Batch Size Impact: While injection molding is highly efficient for large production runs, it might not be as cost-effective for small quantities due to the fixed tooling costs.

Consulting and Planning

In addition to our injection molding services, we also offer a range of value-added services to support our clients throughout the entire manufacturing process. At GDC Manufacturing, we understand that every project is unique and may require specialized knowledge and expertise. That is why consulting services to assist our clients in every step of the manufacturing process is included at no additional cost (minor exceptions apply). Our team of experienced engineers and machinists will work with you to evaluate your project requirements and provide expert advice on the best manufacturing methods, materials, and tolerances to ensure that your project is completed to your satisfaction. With our consulting services, you can have peace of mind knowing that your project is in good hands.

Our team of experts will work closely with you to understand your specific needs and requirements. We will then use our extensive experience and knowledge to develop a comprehensive plan that outlines the best approach for your project. We take into consideration factors such as project timeline, budget, and materials to ensure that we are able to deliver a finished product that meets your expectations and exceeds your requirements. Whether you are looking to create a one-of-a-kind prototype or to bring a new product to market, our team is here to help you every step of the way.

With our commitment to quality, precision, and customer service, we are dedicated to helping our clients achieve their goals and bring their ideas to life.